DTF transfer paper, short for Direct to Film transfer paper, represents a game-changing material in the realm of textile printing and customization. With its unique ability to produce vibrant, high-quality prints on a variety of fabrics, it has become a go-to choice for both amateur and professional creators. This guide explores how to choose the best DTF transfer paper tailored to your specific project’s needs, ensuring you achieve outstanding results every time. From evaluations of DTF paper reviews to understanding the nuances of DTF printing processes, we’ll assist you in navigating through the options available. Get ready to uncover the relevance of DTF transfer paper for fabrics, and elevate your printing experience with the right materials at hand.

Direct to Film printing supplies, particularly referred to as DTF transfer papers, have revolutionized the customization landscape for fabric and apparel. These specialized papers allow for precise and vivid image transfers onto textiles, making them perfect for personalized clothing, designs, and various creative endeavors. When considering how to select the right DTF transfer paper, it’s essential to comprehend the diverse features that can influence the quality and durability of your prints. This guide will discuss the critical factors to evaluate, from the coating quality to the appropriate type of DTF paper for different applications. With insight into user testimonials and expert recommendations, you’ll be equipped to make informed choices that enhance your projects.

The Importance of Choosing Quality DTF Transfer Paper

When it comes to DTF (Direct to Film) printing, the quality of transfer paper directly impacts the final output. High-quality DTF transfer paper ensures clarity and vibrancy in your printed designs, making them stand out on fabric. Choosing the right paper enhances color saturation, allowing prints to resonate beautifully on a range of materials, from cotton to mixed textiles. Additionally, quality papers are essential for achieving long-lasting, wash-resistant results, making your custom apparel desirable and durable.

Moreover, using inferior or low-quality DTF transfer papers can lead to a host of problems, including peeling, fading, and poor adhesion to fabrics. These issues not only affect the aesthetic appeal of the project but can also tarnish your reputation if you’re providing products for clients. Therefore, investing in the best DTF transfer paper available is a critical step that ensures success and satisfaction in your printing endeavors.

How to Choose the Best DTF Transfer Paper

Choosing the best DTF transfer paper involves understanding your specific project needs. Consider factors such as fabric type, ink compatibility, and project application before making a decision. For instance, if you’re working with stretchy fabrics like spandex, a specific type of DTF paper that allows for flexibility and excellent adhesion would be essential. Likewise, understanding whether you will be using water-based or pigment inks can influence your choice, as certain papers are better suited for certain ink types.

Additionally, user reviews and recommendations can provide insightful information on various DTF papers available in the market. Pay attention to feedback regarding the application method, drying times, and durability of prints after washing. These insights will guide you in selecting the most appropriate DTF paper that aligns with your creativity and technical requirements, ensuring the success of your projects.

Understanding DTF Printing Techniques

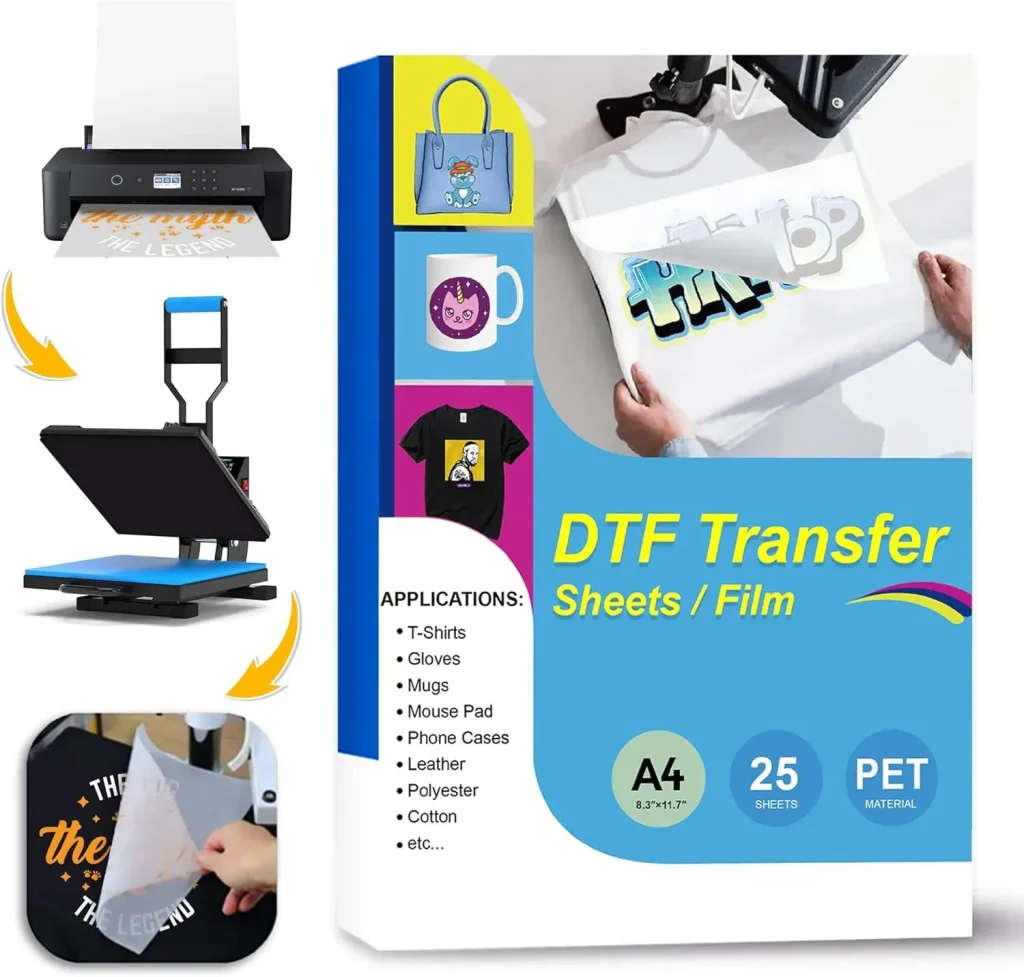

DTF printing is becoming increasingly popular due to its efficiency and the quality of outputs it can achieve. This method involves printing your design onto a special film layer to transfer the image onto fabric using heat and pressure. Unlike traditional methods, DTF printing offers more versatility, as it allows for high-definition prints on a variety of materials, including cotton, polyester, and blends. This multifaceted capability makes it appealing for custom apparel and merchandise.

Furthermore, mastering DTF printing techniques requires familiarity with different types of DTF transfer papers, specifically designed for specific tasks. Some papers are optimized for hot peel applications, while others offer benefits in cold peel processes. Understanding these nuances can improve your overall efficiency and the quality of your prints. By exploring these techniques, you can elevate your printing game while also experimenting with designs that captivate your audience.

Examining DTF Paper Reviews and Recommendations

User reviews provide essential insights into the reliability and quality of different DTF transfer papers in the market. Engaging with various review platforms allows you to gather real-life experiences from users who have faced similar project challenges. They can help you avoid common pitfalls associated with specific brands and identify those that consistently deliver excellent results. Reading reviews also sheds light on how different papers perform across various fabrics.

Additionally, many websites and forums discuss the pros and cons of particular DTF papers based on actual printing experiences. This peer guidance is invaluable for both beginners and seasoned printers seeking to refine their processes. By putting together a collection of honest feedback, you can better position yourself to make an informed choice for high-quality DTF transfer paper, leading to successful and satisfying project outcomes.

Key Features to Look for in DTF Transfer Paper

When selecting DTF transfer paper, understanding key features can significantly influence the quality of your results. Look for papers that offer high brightness and whiteness, as these attributes enhance color accuracy and vibrancy of printed designs on various fabrics. The thickness of the paper also matters; thicker varieties tend to add more durability to prints, ensuring they stand the test of time through washes and wear.

Additionally, consider the coating quality of the DTF paper. A high-quality coating not only improves print adhesion but also enhances washability, ensuring prints remain intact and visually appealing after multiple cycles. Selecting DTF papers based on these critical features will allow you to achieve optimal results while minimizing the risks associated with inferior products.

Practical Application of DTF Transfer Paper for Fabrics

Understanding the myriad applications for DTF transfer paper is crucial when it comes to maximizing its potential. Whether printing custom designs for t-shirts, tote bags, or specialized apparel, all fabric types require specific considerations regarding optimal paper choice. For example, while DTF paper works exceptionally well with cotton, special attention must be paid when applying it to synthetic materials like polyester to ensure adhesion and performance.

Additionally, experimenting with different fabric types can lead to unique outcomes in your projects. It may be beneficial to conduct test prints on various materials before proceeding with full runs. This trial and error can help you gauge how well the DTF transfer paper performs across different fabrics. Such practical applications lead to greater creative palettes and enhance the overall quality of your finalized projects.

Frequently Asked Questions

What is the best DTF transfer paper for printing on fabrics?

The best DTF transfer paper for printing on fabrics varies based on the specific fabric type and intended use. Look for DTF papers with high brightness and a durable coating to ensure vibrant colors and long-lasting prints. Brands like Gildan and Forever are frequently recommended for their quality results on cotton and polyester fabrics.

How to choose DTF transfer paper for my printing projects?

When choosing DTF transfer paper, consider factors such as fabric type compatibility, ink compatibility, and specific features like thickness and coating quality. Cold peel papers are ideal for detailed designs, while hot peel papers are better for quick applications. Testing different papers can also help in making the best choice.

What are the differences in DTF paper reviews on the market?

DTF paper reviews often highlight variations in adhesion quality, color vibrancy, and durability across different brands. User experiences can reveal issues such as peeling or fading after washing, making it essential to compare reviews on sites like Amazon or specialized printing forums to find reliable options.

Can I use DTF transfer paper for dark fabrics?

Yes, you can use DTF transfer paper for dark fabrics, but it’s crucial to choose a type that is designed for high opacity and vibrant colors. Look for DTF papers specifically labeled for dark textiles, as they offer better adhesion and visibility on darker surfaces.

What is the recommended thickness for DTF transfer paper?

The recommended thickness for DTF transfer paper varies based on the type of fabric being used. Generally, thicker DTF papers provide durability and better print quality, while thinner options may offer more flexibility. Testing different thicknesses on your desired fabric is advisable.

How does DTF printing compare to other printing methods?

DTF printing is often compared to methods like DTG (Direct to Garment) and screen printing. Its advantage lies in its ability to print on a wide variety of fabrics with high-quality results and durability. Unlike screen printing, DTF is better suited for smaller runs and custom designs.

| Key Point | Description |

|---|---|

| Introduction | The right DTF transfer paper impacts printing quality for apparel and crafts. |

| Understanding DTF Transfer Paper | DTF paper uses heat and pressure to adhere printed films to textiles, known for durability and color accuracy. |

| Types of DTF Transfer Paper | Includes cold peel and hot peel varieties, and paper that matches ink types. |

| Features to Consider | Look for brightness, thickness, and coating quality for vibrant, durable prints. |

| Application and Fabric Type | Select DTF paper based on the fabric type for best adhesion and results. |

| Trial and Error | Conduct test prints on various fabrics to ensure quality before bulk purchases. |

| User Reviews and Recommendations | Refer to user reviews for insights on the quality and performance of DTF transfer paper. |

Summary

DTF Transfer Paper plays a crucial role in achieving high-quality prints for various projects, ranging from personalized apparel to unique craft items. By carefully considering factors such as the type of paper, ink compatibility, and the specific fabric being used, you can enhance the vibrancy and durability of your prints. Features like brightness, thickness, and the quality of the coating can significantly affect the final product, making it essential to choose wisely. Testing different papers is advised to find the best option for your needs, along with reviewing experiences shared by other users for more informed choices. With this knowledge, you can make confident decisions, ensuring your DTF printing projects turn out beautifully.