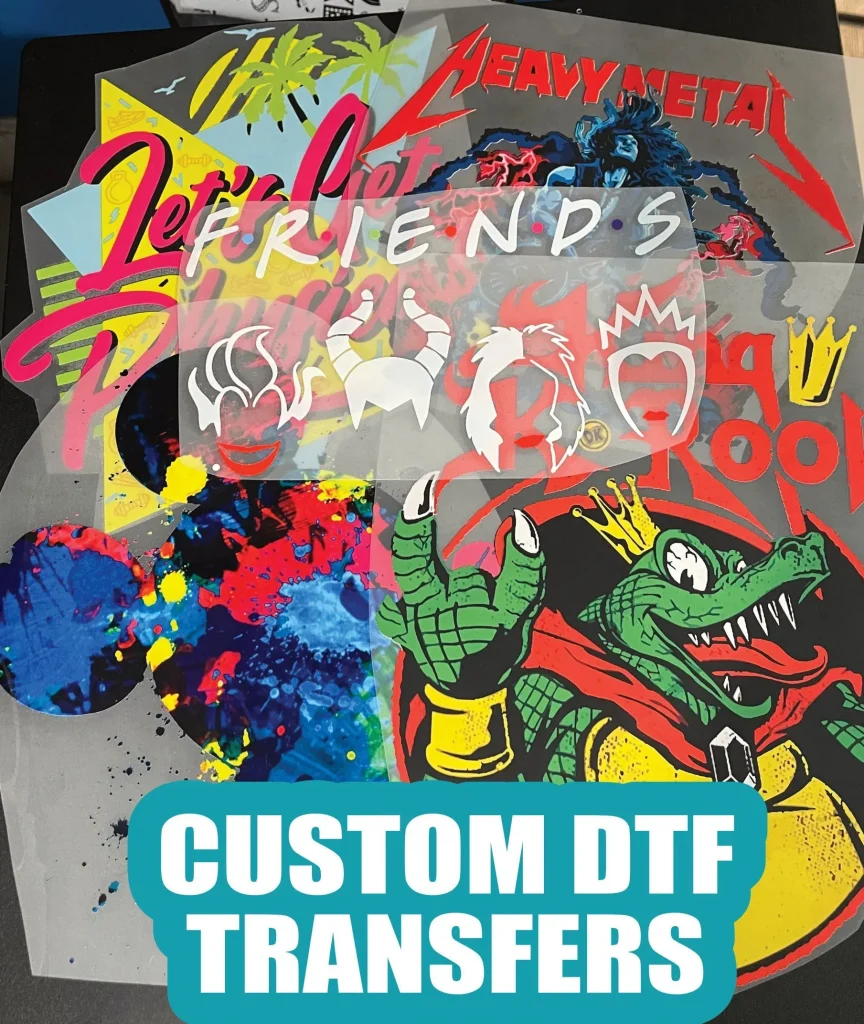

In the realm of custom printing, **DTF Transfers** have emerged as a game-changer for businesses looking to personalize apparel with vibrant and intricate designs. This innovative printing method, known as Direct-to-Film, allows for stunning graphics to be transferred onto various fabric types using advanced print technology. With the ability to produce eye-catching designs on dark materials—where traditional methods like DTG and screen printing often struggle—DTF is quickly becoming the preferred choice for entrepreneurs and e-commerce businesses alike. This article will delve into the advantages of DTF Transfers over other apparel printing methods, including its efficiency, durability, and flexibility. Whether you’re a seasoned business or just starting out, understanding DTF printing is essential for meeting customer demands in today’s competitive market.

Also recognized as Direct-to-Film printing, DTF Transfers provide a modern solution for those in need of high-quality apparel customization. This method stands out among popular processes like Direct-to-Garment (DTG) and screen printing, offering unique benefits that cater to various printing needs. By utilizing specialized films and adhesives, DTF technology ensures that designs maintain their vibrancy and durability, even after multiple washes. For those exploring different apparel printing approaches, understanding the nuances between these methods can significantly enhance your decision-making process. As the demand for personalized clothing continues to rise, becoming acquainted with DTF and its advantages might just set your business apart from the competition.

Understanding DTF Transfers: A Comprehensive Overview

Direct-to-Film (DTF) Transfers represent an innovative approach in apparel printing, simplifying the process of transferring intricate designs onto garments. Utilizing a special film combined with a heat transfer method, DTF allows for crisp images and vibrant colors that stand out. This method caters to various fabric types including cotton and polyester, making it a versatile choice for businesses seeking customization options that appeal to a wide audience.

The technology behind DTF printing emphasizes efficiency and quality, offering rapid production times that suit the fast-paced fashion market. Comparatively, DTF Transfers outshine other methods like Direct-to-Garment (DTG) and screen printing, especially in terms of color vibrancy on darker fabrics. As the demand for unique and colorful designs increases, DTF positions itself as a leading contender in the custom printing industry.

DTF vs DTG: Key Differences Explained

When comparing DTF to Direct-to-Garment (DTG) printing, several critical distinctions arise that can influence a business’s choice of printing method. DTF is designed to overcome the limitations often faced by DTG, particularly with dark fabrics. With DTF, intricate designs can be printed on any color background without loss of detail or vibrancy. This advantage is crucial for brands aiming to diversify their product offerings and reach markets that require a wider palette.

Furthermore, DTF printing boasts superior durability, as the application process includes an adhesive powder that enhances the bond between the ink and fabric. This ensures longer-lasting results, especially compared to DTG, which can sometimes fade faster depending on the fabric and wash experience. For e-commerce brands focusing on quality and performance, choosing DTF vs DTG could be the pivotal decision in delivering customer satisfaction.

The Efficiency of DTF Transfers Compared to Screen Printing

In the realm of apparel printing, screen printing has long been favored for large batch production, but it comes with notable drawbacks in flexibility and complexity. DTF Transfers, on the other hand, provide a rapid turnaround for both small and large orders, making them an increasingly popular choice. With minimal setup time required compared to screen printing, businesses can accommodate last-minute requests or small runs without significant delays.

Moreover, the complexity of designs plays a significant role in the decision-making process; DTF excels here as well. Unlike screen printing, which often demands simpler graphics due to layering limitations, DTF allows for a multitude of colors and intricate artwork without compromising quality. This ability to adapt to modern design trends places DTF Transfers ahead of traditional methods, particularly for brands that pride themselves on creative and bespoke apparel.

Current Trends Influencing DTF Printing Services

The surge in demand for personalized apparel is a driving force behind the adoption of DTF printing, allowing businesses to keep pace with rapidly shifting fashion trends. In an era where consumers crave individuality, DTF printing provides the perfect solution by enabling brands to offer high-quality, customized designs without the extensive setup required by other methods such as screen printing. This trend is particularly evident in the rise of on-demand printing services, allowing businesses to manage inventory efficiently.

Advancements in printing technology have further solidified DTF printing’s place in the market. Stronger inks and improved film quality have revolutionized the landscape, offering even greater durability and washability for printed designs. As these innovations emerge, companies utilizing DTF technologies can confidently meet consumer expectations for lasting quality and vibrant designs, securing their position in the competitive custom printing arena.

Evaluating Your Custom Printing Needs: DTF, DTG, or Screen Printing?

Choosing the right printing method is crucial for maximizing both quality and profitability in apparel production. Factors such as order volume, fabric type, and design complexity should all be taken into account when deciding between DTF, DTG, and screen printing. For businesses focusing on smaller batches or intricate designs, DTF printing often emerges as the superior choice, providing exceptional quality while also reducing waste and inventory challenges.

Conversely, for larger orders with simpler designs, traditional screen printing may yield better cost-efficiency. However, with the capacity for a diverse fabric selection and multi-color designs, DTF transfers can cater to a broader market segment, making them an advantageous option in many scenarios. Understanding these nuances will ensure that businesses can select the most appropriate printing method for their unique needs.

The Future of DTF Transfers in Custom Apparel Printing

As the custom printing industry continues to evolve, DTF transfers are poised to play a significant role in its future. With their ability to produce vibrant, high-quality designs on a broad spectrum of fabrics, DTF technology stands out as a versatile solution for apparel businesses looking to innovate. As consumer preferences shift towards unique and personalized offerings, DTF printing aligns seamlessly with these demands, positioning itself as a cornerstone of modern apparel customization.

Investment in DTF technology and training will be imperative for businesses aiming to keep up with increasing competition and customer expectations. As advancements persist, those who harness the benefits of DTF will not only improve their production capabilities but also enhance their reputation for quality. The future of DTF Transfers is bright, paving the way for an exciting new era in the world of custom apparel printing.

Frequently Asked Questions

What are DTF Transfers, and how do they differ from DTG printing?

DTF Transfers, or Direct-to-Film Transfers, involve printing designs on a special film that is later heat-pressed onto garments. Unlike DTG (Direct-to-Garment) printing, which prints directly onto fabric, DTF excels in color vibrancy and can effectively print on dark fabrics, making it ideal for a diverse range of materials.

What advantages do DTF Transfers offer compared to traditional screen printing?

DTF Transfers provide several advantages over screen printing, including reduced setup time, the ability to produce intricate designs, and flexibility in handling smaller orders. This makes DTF a preferred choice for on-demand custom printing projects.

Can DTF Transfers be used on any fabric type for custom printing?

Yes, DTF Transfers are versatile and can be used on various fabric types, including cotton, polyester, and blends. This flexibility allows businesses to cater to diverse apparel printing needs, unlike some methods that are restricted to specific materials.

How do DTF Transfers handle complex designs compared to other apparel printing methods?

DTF Transfers are exceptional at accommodating intricate designs with multiple colors, outperforming both DTG and screen printing methods, which may struggle with detailed graphics due to their respective limitations in color layering and fabric treatment.

Are DTF Transfers suitable for large production runs in custom printing?

While DTF Transfers are ideal for smaller, customized jobs due to rapid production capabilities, they can also be used effectively in larger production runs. However, for bulk orders of simpler designs, screen printing may still be more cost-effective.

What trends are influencing the popularity of DTF Transfers in the custom apparel market?

Current trends favoring fast fashion and personalization are driving the demand for DTF Transfers. Technological advancements have resulted in stronger inks and films that enhance the washability and longevity of DTF designs, making them increasingly appealing to business owners and consumers alike.

| Printing Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| DTF (Direct-to-Film) | – Vibrant colors on dark fabrics – Versatile on different fabrics – Handles complex designs well |

– Newer technique may lack familiarity for some | – Custom apparel with intricate designs – Small to medium order volumes |

| DTG (Direct-to-Garment) | – Great for detailed prints – Ideal for small batches |

– Limited on dark fabrics – More fabric selective |

– Short-run custom orders |

| Screen Printing | – Cost-effective for bulk orders – Efficient for simple designs |

– Long setup time – Limited design complexity |

– Large quantities of simple designs |

Summary

DTF Transfers are transforming the landscape of custom apparel printing by offering high-quality, vibrant designs that stand out, especially on dark fabrics. Compared to traditional methods like DTG and screen printing, DTF excels in versatility and efficiency, making it an ideal choice for businesses focused on intricate designs and varied fabrics. As consumer demand for personalized products grows, understanding the unique benefits of DTF printing becomes crucial for any entrepreneur aiming to succeed in the competitive custom printing market.