DTF transfers, or Direct to Film transfers, have emerged as a game-changer in the realm of custom printing solutions, particularly for apparel and promotional items. This innovative DTF printing technology allows businesses to create vibrant, high-quality designs that can be easily applied to a variety of fabrics. With its unique benefits, DTF transfers present a cost-effective alternative to traditional methods, enabling smaller companies to compete in a crowded market while minimizing material waste. However, as with any printing method, there are pros and cons of DTF that businesses must consider before fully committing to this approach. In this overview, we will delve into the numerous advantages and potential drawbacks of DTF transfers, helping you make an informed choice for your printing needs.

When discussing Direct to Film transfers, it’s important to recognize this technique as a forefront player in modern printing practices. Many refer to this method as DTF printing, highlighting its innovative capabilities and versatility in the garment industry. This custom printing approach not only enhances design quality but also streamlines production processes, making it an attractive option for businesses seeking efficiency. Exploring additional terminology around DTF, we find discussions centered on DTF transfer benefits and the nuances of the technology that make it a popular choice among brands aiming for creativity and sustainability in their offerings. As we unpack these concepts, understanding the breadth of DTF’s applications will clarify its impact on the evolving landscape of printing technologies.

Understanding DTF Printing Technology

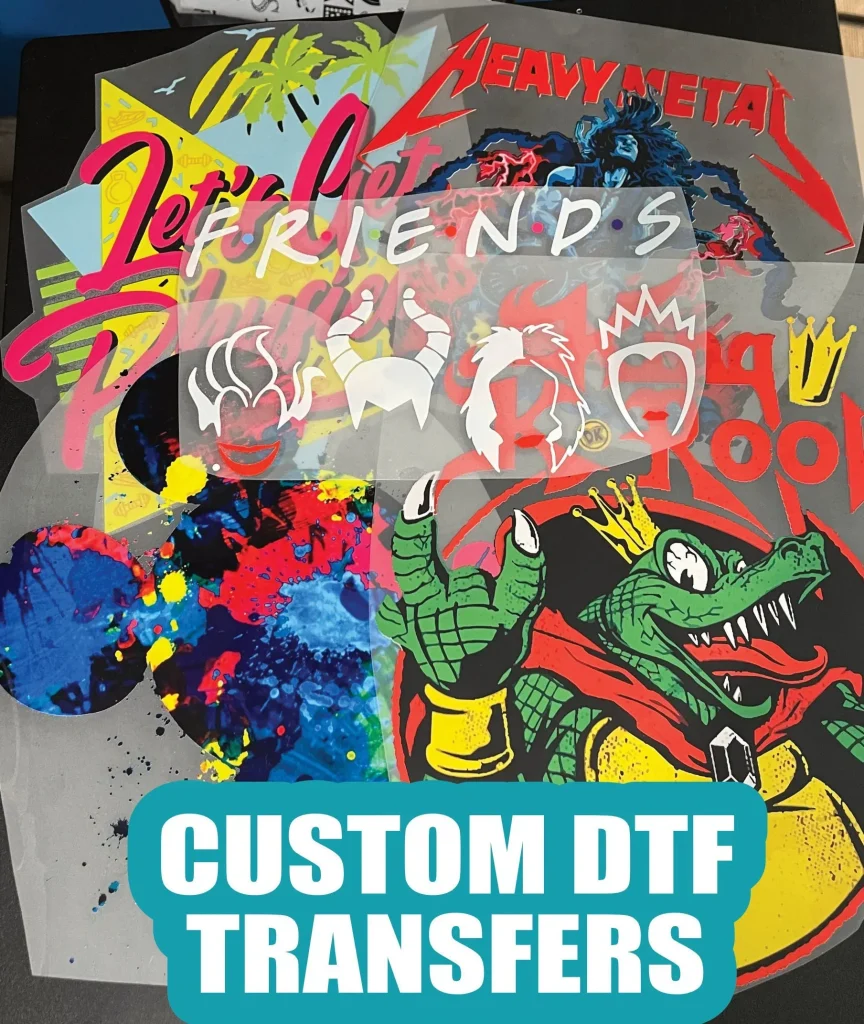

Direct to Film (DTF) printing is a cutting-edge technology that has reshaped the landscape of custom printing solutions. This method involves printing an image onto a special film that can then be transferred onto garments using heat. What sets DTF apart from traditional printing methods, like screen printing, is its ability to produce high-resolution, vibrant prints that adhere well to various fabric types. As such, it offers great versatility, allowing for creative freedom in designing custom apparel and promotional products.

Furthermore, DTF printing eliminates the need for screens, which are typically required in screen printing. This makes the setup process quicker and less resource-intensive, especially for smaller production runs. Users can print multiple designs in one go, which is perfect for businesses looking to cater to specific customer requests without the excessive expenditure associated with traditional printing techniques.

The Cost-Effectiveness of DTF Transfers

Cost-effectiveness is one of the most significant advantages of utilizing DTF transfers for printing needs. With lower initial setup costs than traditional printing methods, such as screen printing, DTF technology allows small to mid-sized businesses to enable their offerings with high-quality prints without breaking the bank. Businesses can save significantly on expenses like screens and setup, thereby allocating funds towards other critical areas of their operations, such as marketing.

Moreover, DTF transfers can minimize material waste due to their efficient use of film and inks. By producing prints that adhere well to various fabrics, businesses can offer a broader range of products without the need for extensive inventory, further enhancing their cost-effectiveness. This combination of reduced costs and increased versatility makes DTF an appealing choice for businesses aiming to maximize profit margins.

Exploring the Benefits of DTF Printing

DTF printing offers a plethora of benefits that make it an attractive option in the realm of custom printing. One of the most notable is the high-quality print outputs it delivers. DTF transfers produce vibrant colors and detailed designs that can endure the rigors of washing and wearing, making them suitable for both everyday apparel and promotional items. This durability ensures that customers remain satisfied with their purchases, which is crucial for building brand loyalty and repeat business.

Additionally, the flexibility of DTF transfers means that they can be applied to a wide variety of materials, including cotton, polyester, and their blends. This versatility allows businesses to cater to diverse customer preferences, making it easier to create a range of customized products. Whether it’s t-shirts for a sports team or promotional items for corporate events, DTF printing can meet these varied requests with ease.

The Drawbacks of DTF Transfers

While DTF transfers offer many advantages, potential users must also consider the drawbacks associated with this technology. One primary concern is the initial investment in equipment, which can be higher than that of more traditional printing methods like heat transfer vinyl. For smaller businesses, the cost of procuring the necessary printing machines and materials may present a significant barrier to entry.

Another downside is the varying quality compared to legacy methods, particularly for intricate designs. While DTF printing excels in many aspects, businesses aiming for ultra-high-quality finishes, such as fine details in printed artwork, may find that DTF falls short in some instances. Consequently, assessing whether DTF transfers will meet the specific quality needs of a business is crucial.

Technical Skills Required for DTF Printing

Implementing DTF printing effectively necessitates a certain level of technical proficiency. Operators must be well-versed in printing software, familiar with managing the printer settings, and understand how to handle the transfer film and adhesives properly. Without these skills, businesses may struggle with efficiently utilizing the technology, leading to potential bottlenecks in production and output quality setbacks.

Furthermore, proper training is essential to maximize the benefits of DTF printing. Companies that invest in skill development will likely see improved output quality and reduced operational errors, enhancing overall efficiency. Without this commitment to staff training, businesses might fall behind in their competitive landscape, ultimately affecting profitability and growth.

Navigating the Competitive Landscape of DTF Printing

As the DTF printing technology gains momentum, the competition within the printing market is intensifying. More companies are adopting DTF transfers into their offerings, which can result in thinner profit margins. This surge in competitors makes it essential for businesses to carve out unique niches and differentiate their services to stand out in a crowded marketplace.

In response to the growing competition, businesses must leverage the advantages DTF technology offers, such as its versatility and high-quality outputs. Creative marketing strategies and a robust understanding of customer needs can help companies maintain a competitive edge. Moreover, continuously refining printing techniques and investing in quality control can enhance brand reputation, ensuring businesses remain a preferred choice for customers seeking custom printing solutions.

Frequently Asked Questions

What are the key benefits of using DTF transfers in printing?

DTF transfers offer several key benefits including cost-effectiveness, versatility, high print quality, efficiency, and reduced material waste. These advantages make DTF technology an appealing choice for businesses aiming to provide custom printing solutions across various fabrics and products.

How does DTF printing technology compare to traditional printing methods?

DTF printing technology is often more cost-effective and versatile than traditional methods like screen printing. While it allows for vibrant prints on various materials, businesses should also consider the initial equipment costs and varying quality for intricate designs when comparing capabilities.

What should businesses consider regarding the pros and cons of DTF transfers?

When evaluating DTF transfers, businesses should weigh the pros such as high-quality prints and reduced waste against cons like initial equipment costs and the need for technical skills. Understanding these factors will help in determining the suitability of DTF printing for their specific needs.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are notable for their versatility and can be applied on a wide range of fabrics, including cotton, polyester, and blends. This makes DTF printing ideal for custom printing solutions across different apparel and promotional products.

What challenges might a business face when adopting DTF printing technology?

Businesses may face challenges such as the initial investment for equipment, the need for skilled operators, and potential issues with adhesive quality. Addressing these concerns is crucial for successfully incorporating DTF transfers into their production line.

Why is sustainability an important factor in DTF printing?

Sustainability is essential in DTF printing as this technology produces less material waste compared to traditional methods. By adopting DTF transfers, businesses can enhance their brand image and appeal to environmentally conscious customers, contributing to a more sustainable printing industry.

| Aspect | Pros | Cons |

|---|---|---|

| Cost-Effectiveness | Lower setup costs compared to traditional methods, appealing for small to mid-sized businesses. | Initial Equipment Cost: Requires significant upfront investment in printers and supplies. |

| Versatility | Applicable to a variety of fabrics (cotton, polyester, etc.), allowing for diverse products. | Quality vs. Quantity: Print quality may not match high-end methods for intricate designs. |

| High Print Quality | Produces vibrant prints that resist wear and tear, enhancing customer satisfaction. | Skill Requirements: Necessitates technical know-how for effective operation of the equipment. |

| Efficiency and Speed | Quicker turnaround times and easy design adjustments beneficial for fast-paced environments. | Adhesive Concerns: Poor application or material quality can affect the final product’s texture and durability. |

| Reduced Material Waste | Produces less waste, appealing to environmentally conscious consumers. | Market Competition: Increasing use of DTF by others can lead to price competition and thinner margins. |

Summary

DTF transfers present a transformative opportunity for businesses aiming to enhance their printing capabilities and product diversity. Known for their cost-effectiveness and high-quality output, DTF printing is rapidly becoming a preferred choice among companies looking to stay competitive in the printing market. This innovative method allows for a wide range of fabric applications, making it ideal for custom apparel and promotional items. While there are upfront costs and technical skills required, the benefits of DTF transfers, including reduced material waste and efficiency, make them a compelling option for modern printing needs.