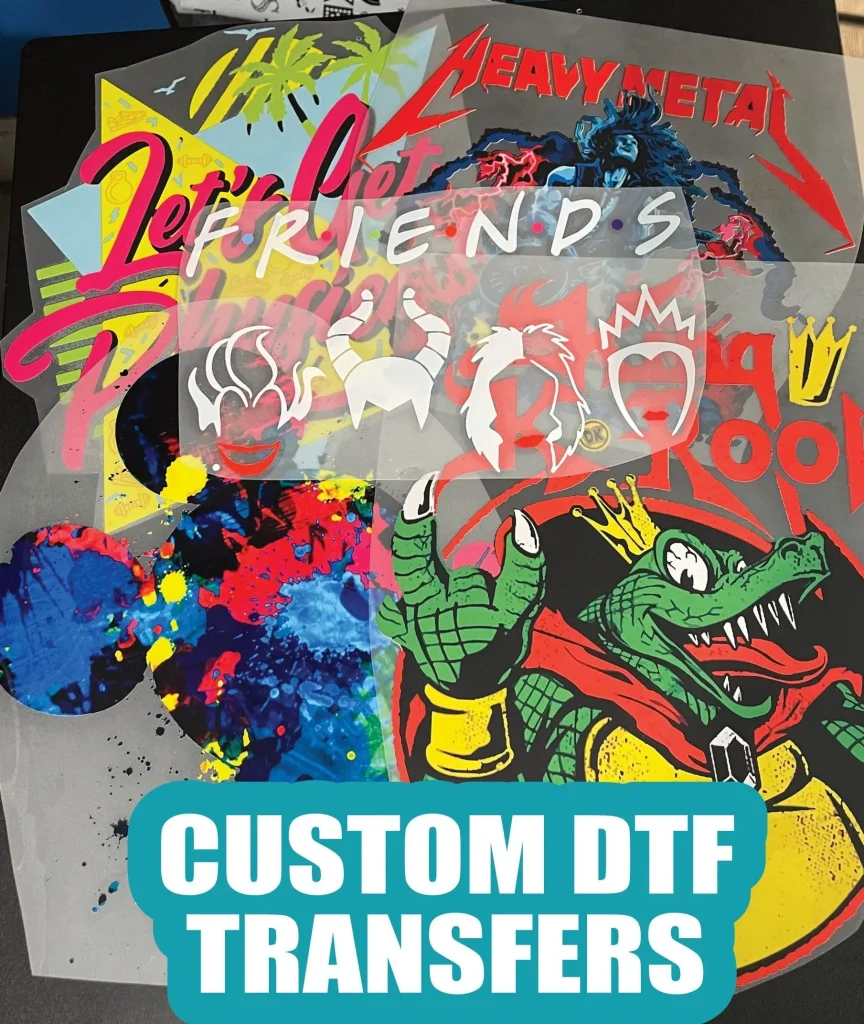

DTF Transfers, or Direct-to-Film transfers, offer an innovative approach to custom apparel printing that’s capturing the attention of creatives and entrepreneurs alike. This cutting-edge DTF printing process allows for vivid and detailed designs to be transferred onto garments with exceptional durability and ease. Whether you’re looking to create unique t-shirts, hoodies, or personalized items, the advantages of DTF printing make it an ideal choice for various fabric types, including cotton and polyester blends. As a beginner’s guide to DTF, this technology breaks down traditional barriers and provides an accessible entry point into the world of custom fashion. Get ready to unlock the potential of your creativity with DTF Transfers, ensuring each print pops with color and quality.

Direct-to-Film printing stands as a revolutionary method in the realm of garment customization, ideal for those eager to explore new creative avenues. This technique harnesses the power of innovative transfer technology to produce high-quality images that are easily applied to a diverse range of fabrics. With its straightforward process and minimal setup costs, beginners can comfortably dive into the captivating world of custom clothing production. The ability to craft detailed graphics with lasting vibrancy has positioned this printing method as a favorite among small business owners and hobbyists. Embrace the wonders of Direct-to-Film applications and elevate your custom apparel creations to the next level.

Understanding the DTF Printing Process

The DTF printing process is a unique technique that revolutionizes custom apparel printing. It begins with a high-resolution design being printed onto a specialized film using a DTF printer. This film is specially coated to allow the ink to adhere effectively while also ensuring bright and vivid graphics. Once printed, an adhesive powder is applied to the wet ink, and the film is heated to activate this adhesive. This crucial step prepares the design for transfer, ensuring that it will bond quickly and securely when pressed onto fabric.

After the adhesive activation, the film is then placed onto the chosen garment, where a heat press applies pressure and heat to transfer the design. One of the significant advantages of this process is its versatility. DTF transfers can be used on various fabric types, from cotton to polyester blends. This adaptability makes it an excellent choice for custom apparel printing, accommodating numerous styles and preferences without the need for extensive preparation.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, involve printing designs on a special film and then using heat and pressure to transfer these designs onto garments. This DTF printing process allows for vivid colors and durability across a range of materials, making it ideal for custom apparel.

What are the advantages of DTF printing compared to other methods?

The advantages of DTF printing include durability, vibrant colors, and versatility in fabric compatibility. Unlike traditional methods, DTF transfers do not require extensive pre-treatment and offer excellent wear resistance, making them a popular choice for custom apparel.

What equipment do I need to start making DTF Transfers?

To get started with DTF Transfers, you’ll need a reliable DTF printer, a heat press, transfer film, and high-quality adhesive powder. Investing in quality equipment is essential for achieving the best results in your custom apparel printing.

Can DTF Transfers be used on all types of fabrics?

Yes, one of the key advantages of DTF printing is its versatility—it can be used on various fabrics, including cotton, polyester, and blends. This makes DTF Transfers a great option for creating custom apparel across different material types.

Is there a beginner’s guide for learning DTF Transfers?

Yes! There are many resources available, including online tutorials and courses tailored for beginners. A beginner’s guide to DTF can help you understand the equipment, materials, and processes, making it easier to master custom apparel printing.

What common applications are there for DTF Transfers in custom apparel?

Common applications for DTF Transfers include creating custom t-shirts, hoodies, tote bags, and personalization projects. This technique is especially popular among e-commerce businesses that focus on custom products due to its ease of use and adaptability.

| Key Point | Details |

|---|---|

| Process Overview | Three main steps: printing on film, applying adhesive powder, curing the design. |

| Advantages | Material versatility, color vibrancy, ease of use. |

| Equipment Needed | DTF printer, heat press, transfer film, adhesive powder. |

| Common Applications | Custom apparel (t-shirts, hoodies), personalization projects. |

| Current Trends | Growing e-commerce interest, increase in educational resources for beginners. |

| Advantages of DTF | Durability, quality, customization options, low setup costs. |

Summary

DTF transfers represent a transformative method for customizing apparel, allowing creators to produce high-quality designs with impressive durability. This technology’s versatility enables it to cater to a broad range of fabrics, making it the ideal choice for both hobbyists and business owners alike. As the realm of DTF Transfers continues to evolve, aspiring users are encouraged to explore the multitude of resources available to help enhance their skills and offerings in the custom apparel market. Embrace the future of garment printing and let the creativity of DTF transfers inspire your projects!