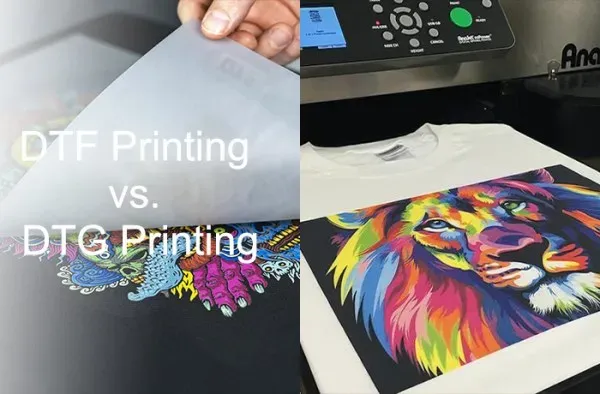

In the vibrant realm of custom apparel printing, the debate between DTF vs. DTG printing has captured the attention of designers and entrepreneurs alike. Both Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing techniques offer unique advantages that cater to specific design needs and fabric types. DTF printing is known for its versatility and durability, while DTG excels at producing intricate, high-quality designs. This comprehensive comparison will delve into the specifications, benefits, and limitations of each method, equipping you with the knowledge needed to make an informed decision for your printing projects. Whether you’re a small business owner or a creative designer, understanding these printing methods comparison will ultimately enhance your custom apparel offerings and customer satisfaction.

When choosing between DTF and DTG printing, it’s crucial to explore different facets of these advanced printing techniques. Direct-to-Film (DTF) allows for transfers from a film onto various fabrics, making it a preferred choice for those looking for flexibility in materials. On the other hand, Direct-to-Garment (DTG) printing utilizes inkjet technology directly on garments, providing stunning, colorful prints particularly effective for detailed artistry. Understanding these fundamental differences will help you determine which method aligns with your creative vision and business objectives. By evaluating aspects like durability in printing and cost efficiency, you’ll be better equipped to select the best approach for your custom apparel needs.

Understanding DTF and DTG Printing

DTF (Direct-to-Film) and DTG (Direct-to-Garment) are two prominent printing methods that cater to the custom apparel industry. DTF printing uses specialized film that transfers the design onto fabric with the aid of heat. This method is gaining traction for its ability to print on a wide array of materials including cotton, polyester, and blends, yielding vibrant and durable results. On the other hand, DTG printing directly applies ink onto the garment, utilizing inkjet technology to produce intricate and high-quality designs. Each method is suitable for different applications depending on the specific needs of garment decorators.

In the realm of design complexity, DTG printing excels with detailed multi-color artwork that requires precise rendering. However, its dependency on fabrics, primarily natural fibers, can present limitations. In contrast, DTF’s versatility with fabric types extends its usability, allowing businesses to expand their offerings without being confined to cotton. As both methods evolve, understanding their capabilities helps businesses choose the most efficient solution for their printing needs.

Advantages of DTG Printing

One of the standout advantages of DTG printing is its ability to produce high-resolution prints with exceptional detail. This method works especially well for designs that require a vibrant color palette and intricate graphics. When the right cotton fabric is used, the results can be stunning, providing wearers with comfortable apparel that embraces the artwork seamlessly. For personalized orders or small runs, DTG allows for quick turnarounds, which can elevate customer satisfaction and retention.

Moreover, DTG printing results in softer prints compared to traditional methods. The ink penetrates the fabric fibers, resulting in a finished product that feels light and smooth against the skin. This comfort factor makes DTG printing particularly popular for custom t-shirts and fashion collections where the touch and feel of the apparel are vital. However, while the benefits of detail and softness are noteworthy, businesses should keep an eye on the potential durability issues associated with DTG prints.

Advantages of DTF Printing

DTF printing boasts several advantages, notably its versatility across different fabric types. This method allows businesses to print on a wider range of textiles, including polyester and cotton blends, thereby expanding their inventory options. With its capacity for vibrant colors and high durability, DTF printing is an excellent choice for creating long-lasting designs that withstand frequent washing. This capability is particularly beneficial for products like sportswear and uniforms, which require enhanced durability.

Additionally, the lower setup costs associated with DTF printing make it an appealing option for small to medium-sized custom apparel businesses. The technology is designed to reduce waste and streamline the printing process, making it easier for designers to experiment with new styles. This adaptability not only aids in keeping costs manageable but also allows for on-demand printing, which is highly sought after in the ever-evolving fashion landscape.

DTF vs. DTG: A Comparative Analysis

When conducting a comparison of DTF vs. DTG printing, various factors come into play. DTG printing is revered for its ability to capture intricate details, making it the go-to for complex multi-color designs on natural fabrics. Conversely, DTF’s adaptability across numerous fabric types makes it a standout option for businesses looking to diversify their offerings. The decision between the two methods should reflect the type of designs one aims to produce while aligning with the target market’s preferences.

Durability is another critical factor where DTF often takes the lead. With superior resistance to fading, prints created using the DTF method tend to outlast those produced by DTG. This advantage becomes crucial for items like workwear or promotional products that may undergo rigorous use. Ultimately, the right printing method will depend on individual business objectives, design requirements, and budget considerations.

Cost Considerations in Printing Methods

Cost is a significant determinant in the choice between DTF and DTG printing. DTG printing can be more expensive, particularly for smaller runs due to its setup processes. The requirement for high-quality cotton fabrics also adds to the overall expenditure for businesses engaging in DTG. Hence, it is often more cost-effective for larger orders, where the price per unit decreases significantly.

On the other hand, DTF printing tends to offer a more appealing cost structure for small to medium-sized businesses due to lower initial setup costs. The ability to print on a variety of materials without needing extensive preparation makes DTF favorable. Moreover, lower waste generation during the printing process can lead to additional savings, making DTF a compelling option for businesses conscious of their budget.

Emerging Trends in Custom Apparel Printing

The printing industry is evolving with significant trends shaping the future of custom apparel. One notable trend is the increasing preference for DTF printing, mainly driven by its versatility and durability. Entrepreneurs and garment producers are gravitating toward DTF for its ability to cater to on-demand services, allowing businesses to respond quickly to market needs without excessive inventory. This shift toward personalization and fast fashion requires responsive printing technologies that DTF aptly provides.

Moreover, advancements in printing technology are continually refining both DTG and DTF processes. Innovations are aimed at enhancing print quality, efficiency, and environmental sustainability, ultimately benefiting both businesses and consumers. As the pressure for eco-friendly practices intensifies, printing methods are being optimized to minimize waste while maintaining high standards of quality and durability. Keeping abreast of these trends will enable garment decorators to stay competitive in a dynamic market.

Frequently Asked Questions

What are the key differences between DTF printing and DTG printing?

DTF printing uses inkjet technology to print designs onto a film, which is then heat-applied to fabrics, making it versatile across multiple materials. In contrast, DTG printing directly applies ink onto the garment, providing detailed and vibrant designs but is best suited for cotton fabrics. The main differences lie in fabric compatibility, durability, and cost-effectiveness.

Which method provides better durability, DTF printing or DTG printing?

DTF printing typically offers better durability compared to DTG printing. DTF prints are resistant to fading, making them ideal for items that undergo frequent washing. In contrast, DTG prints may fade more quickly, especially on blends and non-cotton fabrics.

Is DTF printing suitable for small custom apparel orders compared to DTG printing?

While DTF printing can handle small orders, it often has longer turnaround times due to the film transfer process. DTG printing, however, is particularly efficient for small custom apparel orders, allowing for quick and detailed designs without the need for screens or films.

What fabrics are best for DTF printing and DTG printing?

DTF printing is versatile and works well on various fabrics, including cotton, polyester, and blends. On the other hand, DTG printing is ideal for 100% cotton fabrics, as synthetic materials can affect print quality and durability.

How do DTF printing and DTG printing compare in terms of cost?

DTF printing usually has lower setup costs, making it attractive for small to medium-sized businesses. However, DTG printing can be more cost-effective for larger orders, as the cost per unit decreases with volume. This highlights the need for careful cost consideration when selecting between these printing methods.

Which printing method is better for intricate designs, DTF or DTG printing?

For intricate designs that require multiple colors and high detail, DTG printing is generally a better choice. Its direct-to-garment approach allows for a greater color spectrum and finer detail, whereas DTF printing, while capable, may not achieve the same level of detail with extremely complex designs.

| Feature | DTF Printing | DTG Printing |

|---|---|---|

| Definition | Transfers designs onto fabric using heat from a special film | Uses inkjet technology to print directly onto the fabric |

| Fabric Compatibility | Works well on cotton, polyester, and blends | Best on 100% cotton fabrics; struggles with synthetics |

| Design Advantages | Vibrant colors, durable finish; good for customization | Excellent for complex designs with many colors |

| Durability | More resistant to fading and washing | May fade quicker, especially on blends |

| Setup Costs | Lower initial setup costs | Higher cost per unit for small runs |

| Turnaround Time | Longer for small runs due to film transfer | Faster for smaller orders due to no setup |

Summary

DTF vs. DTG printing presents distinct advantages and considerations for businesses and designers in the custom apparel market. While DTG specializes in detailed, vibrant designs achieved through direct ink application, it faces challenges with cost-effectiveness and fabric limitations. DTF, however, stands out for its versatility across various materials and its durability, making it suitable for a wider range of applications. Understanding the nuances of each method is critical to making informed decisions based on design needs, budget constraints, and material preferences, ultimately leading to successful apparel production.