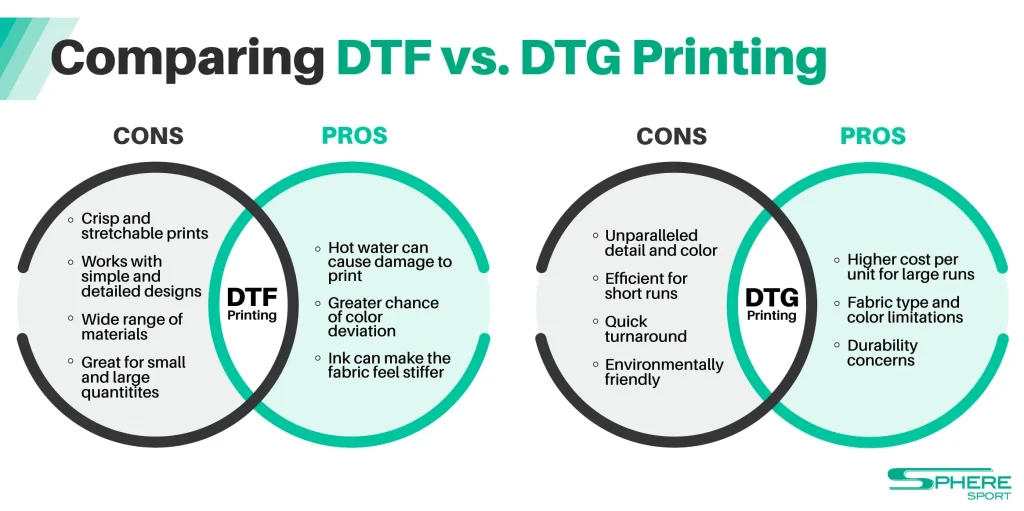

When it comes to graphic printing, the debate between DTF vs DTG is increasingly relevant for those in the apparel industry. These two printing technologies, Direct-to-Film (DTF) and Direct-to-Garment (DTG), each bring unique qualities and techniques to the table, making the choice between them crucial for achieving optimal print quality and durability. DTF employs a specialized transfer film, allowing for application on a variety of fabrics, including those darker materials that DTG might struggle with. On the other hand, DTG leverages advanced inkjet technology to produce intricately detailed designs with vivid colors, particularly beneficial for small runs. By understanding the key differences in these printing techniques, businesses can better align their choices with their specific printing needs, ultimately enhancing their product offerings.

In the world of apparel production, the choice between direct-to-garment printing and direct-to-film printing often dictates the effectiveness of print outcomes. Direct-to-garment, commonly known as DTG, utilizes state-of-the-art inkjet methods to apply ink directly to textile surfaces, while direct-to-film, or DTF, involves printing designs onto film before transferring them onto fabric. This printing techniques comparison highlights critical variances, such as fabric compatibility and durability of printed designs. For enterprises aiming to optimize their print processes, understanding the nuances of these technologies is essential. Both methods have their merits, catering to differing production needs and fabric types, thereby shaping the overall quality and longevity of apparel designs.

Exploring Direct-to-Garment (DTG) Printing

Direct-to-Garment (DTG) printing stands out as a vibrant and intricate method for garment decoration. Utilizing advanced inkjet technology, this process enables direct application of ink onto the fabric surface. The result is a strikingly detailed print with a wide color range that enhances the visual appeal of t-shirts, hoodies, and other clothing items. DTG is particularly beneficial for small to medium-sized runs where customization and precision are paramount, making it a popular choice for boutiques and personalized apparel businesses.

One of the most significant advantages of DTG is its ability to produce high-resolution prints with a soft hand feel. The ink effectively penetrates the fabric fibers, resulting in a finish that feels natural rather than overly rigid or plasticky. Additionally, minimal initial investment costs make DTG an attractive option for businesses looking to create one-off prints without incurring extensive setup expenses typically associated with traditional screen printing techniques.

Understanding Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing represents a revolutionary advancement in garment decoration, allowing for versatility across various fabric types. This technique involves printing designs onto a specialized transfer film, which is then applied to the fabric through heat and pressure. One of DTF’s standout features is its ability to print effectively on a diverse range of materials, including dark and synthetic fabrics that often present challenges for other methods like DTG.

Furthermore, DTF is celebrated for its durability; prints made through this method are resistant to fading, cracking, and peeling. This resistance makes DTF an ideal choice for garments that undergo frequent washing and wearing. The ability to produce multiple prints from a single transfer film also significantly enhances production speed, making DTF a go-to option for businesses tackling bulk orders without compromising on quality.

DTF vs DTG: Key Differences in Print Quality

When comparing DTF and DTG, the quality of the finished product is a critical factor. DTG excels in producing vibrant colors and detailed imagery, making it perfect for designs that need to capture precious details, gradients, and complex patterns. However, the durability of DTG prints can vary, sometimes leading to a decline in quality after multiple washes depending on fabric type and pretreatment processes.

On the other hand, DTF is renowned for its exceptional durability, meaning that prints can withstand extensive use without significant wear. The film transfer used in DTF adheres strongly to the fabric, ensuring that colors remain vivid and intact, even after repeated laundering. In essence, while DTG may create visually stunning prints ideal for short-term use, DTF provides a more reliable option for long-lasting apparel.

Cost Comparison: DTF vs DTG Printing Methods

Cost efficiency is a significant consideration for businesses when choosing between DTF and DTG printing techniques. Direct-to-Garment printing is generally more economical for smaller orders, particularly because it incurs lower initial setup costs due to its direct printing approach. However, when businesses grow and look towards larger production runs, the per-print cost for DTG can become higher due to longer production times and the necessity of detailed pretreatment.

Conversely, Direct-to-Film printing can become highly cost-effective for larger quantities. Despite requiring additional materials, such as transfer films and adhesive powders, DTF allows businesses to maximize output from a single transfer. This results in a lower cost per item over larger runs. Therefore, organizations that focus on bulk production often favor DTF for its economic advantages, especially when the scalability of production is a core requirement.

Production Speed: Evaluating DTG and DTF Efficiency

When examining production speed, it’s essential to distinguish between DTG and DTF printing processes. Direct-to-Garment printing often involves a more prolonged setup due to the pretreatment of fabrics and the need for thorough cleaning between prints. This not only slows down production but can also cause delays, especially for businesses attempting to meet high demand in a timely manner.

In contrast, DTF printing offers faster production speeds that cater well to bulk orders. The ability to apply multiple prints from a single transfer film streamlines the process and enhances overall workflow efficiency. As a result, businesses looking to fulfill large orders quickly may find DTF appealing, particularly when time constraints are in play.

Environmental Considerations in Printing Technologies

With growing awareness of environmental concerns, the ecological footprint of printing methods has gained attention. Both DTF and DTG can utilize eco-friendly inks; however, DTF’s use of certain adhesive components raises questions about its environmental impact. It is crucial for businesses to consider the sustainability of their printing processes as consumers increasingly demand environmentally responsible practices.

Additionally, the waste produced during printing processes is a significant factor. DTG generally generates less physical waste due to its direct printing nature, while DTF methods may produce more offcuts and surplus materials. Businesses must weigh these factors when deciding between DTF and DTG, as sustainability becomes an integral component of brand identity and consumer choice.

Frequently Asked Questions

What are the main differences between DTF vs DTG printing?

DTF (Direct-to-Film) printing transfers designs from a film onto fabric, whereas DTG (Direct-to-Garment) printing uses inkjet technology to apply ink directly onto garments. DTF is more versatile with fabric types and offers greater durability, while DTG provides high-resolution, detailed prints suitable for smaller runs.

Is DTF printing suitable for dark fabrics compared to DTG?

Yes, DTF (Direct-to-Film) printing is highly compatible with dark fabrics and various materials, whereas DTG (Direct-to-Garment) printing can struggle with color vibrancy on darker garments. DTF’s adhesion ensures that colors appear vibrant even on these challenging backgrounds.

How does print quality durability differ in DTF vs DTG?

In terms of durability, DTF prints are known for their resistance to fading, cracking, and peeling, which makes them ideal for everyday wear. DTG prints can vary in durability based on garment pretreatment and fabric type, potentially leading to wear over time.

What production speed advantages does DTF have over DTG?

DTF (Direct-to-Film) printing allows for faster production rates as multiple prints can be achieved from a single film transfer. In contrast, DTG (Direct-to-Garment) printing is generally slower due to the need for individual garment pretreatment and cleaning between prints.

Which printing technique is more cost-effective for large orders, DTF or DTG?

DTF printing becomes more cost-effective for large orders as it maximizes use of transfer films, reducing per-item costs. DTG can be more economical for small batches, but costs tend to rise with larger production due to longer processing times and maintenance.

What environmental considerations should I be aware of with DTF vs DTG printing?

Both DTF and DTG can utilize eco-friendly inks. However, DTF may involve additional adhesive materials that could impact environmental sustainability. DTG printing typically generates less waste, making it a potentially greener option overall.

| Feature | DTG (Direct-to-Garment) | DTF (Direct-to-Film) |

|---|---|---|

| Print Quality & Durability | High-resolution with rich colors; durability varies based on garment treatment. | Excellent durability and adherence to fabrics, resists fading and cracking. |

| Cost Efficiency | Cost-effective for small batches; higher costs for larger orders due to longer production. | More cost-effective for larger runs despite higher initial material costs. |

| Production Speed | Generally slower due to garment preparation and cleaning. | Faster production capabilities, suitable for bulk orders. |

| Environmental Impact | Less physical waste; eco-friendly inks available. | Potential for higher waste due to extra materials used, but eco-friendly options exist. |

Summary

DTF vs DTG highlights the critical differences between these two popular garment printing methods. Direct-to-Garment (DTG) excels in high-resolution, detailed prints suitable for small runs, providing a soft feel on finished products. On the other hand, Direct-to-Film (DTF) is versatile, accommodating various materials and offering durability ideal for larger quantities. Both methods have their unique benefits and limitations, making the choice between DTF and DTG dependent on the specific needs of your printing projects. Whether prioritizing print quality or production speed, understanding these factors will greatly assist in optimizing your garment printing process.